品牌

生产厂家厂商性质

上海市所在地

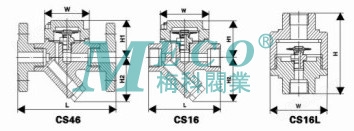

热静力膜盒式蒸汽疏水阀 Thermal diaphragm steam trap

产品介绍:膜盒式蒸汽疏水阀主要动作元件金属膜盒,膜盒内根据热胀冷缩原理开启和关闭阀门。广泛用于蒸汽主管线、伴热管线、干燥器和工业加热蒸汽设备系统,供热采暖片上是的选择。

结构特点:

1、结构简单,维护方便。

2、部件全部采用合金处理的不锈钢,耐磨耐气蚀,使用寿命长。

3、排空能力强,排水迅速,安装方式随意。

4、可以实现多个膜盒组合,使用于大的排量场合。

5、零泄漏,背压率达到75%以上。

Introduction:The main part of the diaphragm trap os metallic diaohragm.Inside the diaphragm,the valve will be opened and closed in compliance with the principle of metal expand on heating and contract on cooling.This kind of trap enjoys extensive application in main pipelines,heat accompanying pipelines,drier and heating equipment.It is your best choice for heating equipment.

Sreuctures:1.Simple structure will facilitate maintenance.

2:All the parts are made of stainless steel with long service life and abilities to resist abrasiveness.

3.Excellent abilities to discharge gas;able to tapidly discharge water;the inatallment can be conducted in free way.

4.Several diaphragms can be combined to serve the working places needing large fas amount discharged.

5.No leakage,the rate of back pressure up to above75%.

主要零件材料和性能参数 Main parts and specifications

| 主要零部件材料表 | Parts | Materials |

| Body/Bonnet | A105 | |

| Seat | Tungsten chromium cobalt alloy | |

| In sets Filters | 1Cr18NNi9Ti | |

| Nembrane Box | Kazak alloy |

| Model 产品型号 | Nominal diameter | Connection | Pressure rating(MPa) | Max allowable(℃) | Extermal dimensions(mm) | Re.weight | |||

| L | H1 | H2 | W | ||||||

| CS16H-16C | 15~20 | Thread 螺纹 | 0.01~1.6 | 250 | 100 | 52 | 62 | 70 | 2.5 |

| 25 | 120 | ||||||||

| 32~40 | 150 | 68 | 68 | 90 | 5 | ||||

| 50 | 160 | ||||||||

| CS46H-16C | 15~20 | Flange 法兰 | 0.01~1.6 | 250 | 150 | 52 | 62 | 70 | 4.9 |

| 25 | 250 | 160 | |||||||

| CS46H-16C | 32~50 | Flange 法兰 | 0.01~1.6 | 250 | 230 | 85 | 60 | 120 | 13 |

| CS46H-16AA | 65~100 | Flange 法兰 | 0.01~1.6 | 250 | 310 | 120 | 95 | 150 | 24 |

| CS46H-25A | 20~50 | Flange 法兰 | 0.01~1.6 | 300 | 230 | 85 | 60 | 120 | 14 |

| CS46H-16L | 15~25 | Thread(Stand)螺纹(立式) | 0.01~1.6 | 250 | 100 |

|

| 80 | 2.3 |

| CS46H-16F | 15~25 | Angle Thread 角式螺纹 | 0.01~1.6 | 250 | 53 | 103 | 55 |

| 1.5 |

维护与检修

疏水阀运行期一般为12个月,到期打开出口体清除脏物,清洗滤网,如介质杂质较多,可以酌情提前清洗。疏水阀由于使用过久可能有封闭不严现象,这时,要及时更换或维修(如维修:打开出口体,把阀盖卸下打开,检查阀片,阀座密封是否磨损。可以用600目金钢砂混机油在平台上研磨,达到电二件互为密封为止。)

| 故障现象 | 可能原因 | 解决方法 |

| 漏汽 | 1 .阀片、阀座的密封面严重磨损; | 研磨密封面,使其达到密封; |

| 2 .密封面上存有污垢或水锈 | 打开阀盖清除污垢或水锈 | |

| 3 .阀前无凝结水、蒸汽过热 | 关闭疏水阀前截止阀 | |

| 连续排水 | 阀盖没有拧紧或者阀盖有泄漏蒸汽直接进入控制,使阀片打不开。 | 旋紧阀盖或排除泄漏处,可用耐高温密封胶修补泄漏处 |

◇ 阀门类:【A】安全阀【D】蝶阀 电磁阀【F】放料阀【G】隔膜阀 管夹阀 过滤器【H】呼吸阀【J】 截止阀 减压阀【P】排泥阀 排气阀 排污阀 平衡阀【Q】球阀 切断阀【S】 疏水阀 水力控制阀【T】调节阀【X】旋塞阀【Z】闸阀 针型阀 止回阀 柱塞阀 阻火器。