德国哈莫尔曼高压泵HAMMELMANN柱塞泵水泵

品牌

生产厂家厂商性质

西安市所在地

德国哈莫尔曼高压泵HAMMELMANN柱塞泵水泵

Founded in 1949 by Paul Hammelmann in Oelde, Westphalia, the company decided to start manufacturing high-pressure pumps and cleaning systems in 1955

thus laying the foundations of the current business. Hammelmann became a pioneer in the field of hydrodynamics and was responsible for many trailblazing innovations.

该公司由Paul Hammelmann于1949年在威斯特伐利亚州厄尔德创立,决定于1955年开始生产高压泵和清洁系统,从而为当前的业务奠定了基础。哈莫尔曼成为流体动力学领域的早行者,并负责了许多开创性的创新。

In endeavoring to solve individual problems and improve existing solutions, the company has grown from modest beginnings into an internationally recognized manufacturer of high-pressure technology products.

The plant in Oelde boasts state-of-the-art machinery and covers an area of 30,000 square meters.

The DP 60 was the first pump produced in Oelde. It had an operating pressure of 60 bar and a flow rate of 60 l/min and was used for cleaning applications in the paper industry.

Today, we can achieve operating pressures of over 4000 bar and flow rates up to 3000 l/min with Hammelmann high-pressure pumps.

Decades ago, the point of fitting a cover over a high-pressure unit was just that. Today, the covers have more to do in controlling sound and exhaust emissions.

Hammelmann also supplies individual elements such as dust particle filters and electronic microprocessors and controllers.

During the mid-1960s, operating pressures only reached 500 bar. In 1974, Hammelmann revolutionized high-pressure technology with the introduction of the friction-free plunger seal assembly.

This metal-to-metal sealing system enabled operating pressures of up to 2000 bar to be reached for the first time together with a high service life.

In 1969, Hammelmann launched the Dockmaster as the first semi-automatic ship cleaning machine. Today’s version of the unit is environmentally friendly and features direct suction, and is not only used in shipyards but also for the selective removal of concrete in road construction.

Nowadays, water tools are used more and more in automatic cleaning processes. Cleaning cast parts is just one of many examples.

Whereas these previously could only be cleaned by hand (if at all), robots now carry out the work with the help of high-pressure technology made by Hammelmann.

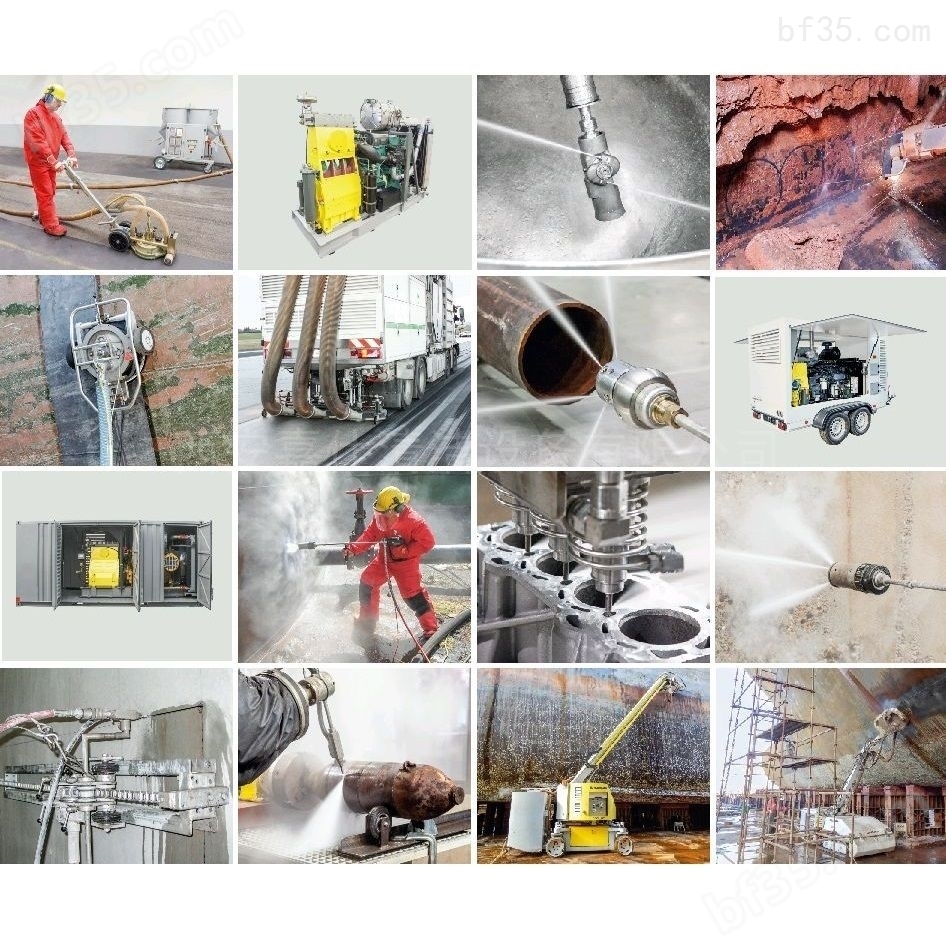

喷砂,商业清洁,容器清洗,排水清洗,外墙清洗,地板清洗,高压清洗,工业清洗

abrasive blasting,commercial,container cleaning,drain cleaning,facade cleaning,floor cleaning,high pressure cleaning,industrial cleaning

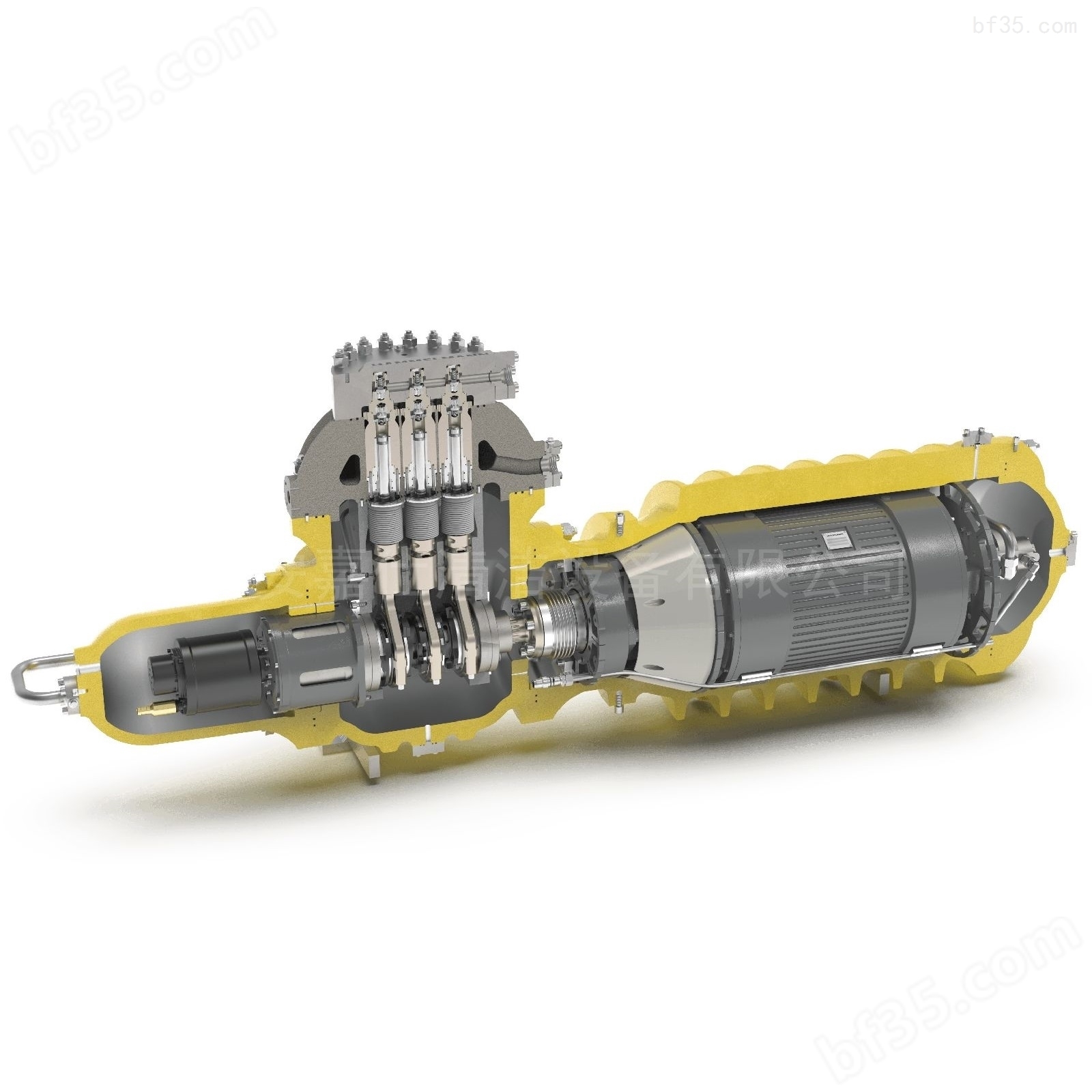

高压柱塞泵HAMMELMANN高压泵的工作机理

HAMMELMANN高压柱塞泵属于容积式泵,借助工作腔里的容积周期性变化来达到输送液体的目的;原动机的机械能经泵直接转化为输送液体的压力能;

SPECK高压泵的容量只取决于工作腔容积变化值及其在单位时间内的变化次数,理论上与排出压力无关。

HAMMELMANN高压柱塞泵是借助于活塞在液缸工作腔内的往复运动(或通过隔膜、波纹管等挠性元件在工作腔内的周期性弹性变形)来使工作腔容积产生周期性变化的。

在结构上,SPECK高压泵的工作腔是借助密封装置与外界隔开,通过泵阀(吸入阀和排出阀)与管路沟通或闭合。

HAMMELMANN柱塞清洗水泵HAMMELMANN高压泵哈莫尔曼销售后调试注意事宜

HAMMELMANN高压泵开机1-2小时检查各部温度、压力、声音是否正常。

请注意如下事项:HAMMELMANN高压柱塞泵装置完毕试机。

一 试机前的检查

电源有良好接地。

1确认哈莫尔曼高压水泵电源电压及接线正确。

2确认管路、泵件、压力表、平安阀无异常(因运输等原因可能有损坏)

二 注油

1确认哈莫尔曼高压柱塞泵机座油池干净。

油的牌号按油标指示位置注油,2向机座油池内注入润滑油。

不同的型号HAMMELMANN高压泵使用润滑。坚持位在高与低油位之间。

液力端各法兰螺钉要适度(约530N.M不要用力太大。

三 检查HAMMELMANN高压水泵各部螺钉有无松动。

以防压坏“上套”检查电动机联轴器、电接点压力表、电气设备是否正常。

四 检查附件是否正常。

五 电接点压力表上限是否调节在1.1倍的额定压力值上。

六 试机

电接点压力表指示在1.1倍的额定压力值下,将吸入管道、排出管道上的所有阀门开启到大位置。

确认HAMMELMANN高压柱塞泵平安阀正常。方可启动主机。

开启主机。

1严禁在关闭入口阀门的情况下。

2确认油罐中油面位置正常。

马达开始起动。3按下起动开关。

4检查马达转向是否正确。

检查有无异常响声。

5开机后。机件有无松动,各密封件有无泄漏。

6观察压力HAMMELMANN高压柱塞泵表值是否指示在额定值。

HAMMELMANN高压水泵日常运转中注意事项

1入口压力表指示值是否正常。

要做到尽早发现事故苗头。

2注意声音和振动有无异常。

润滑油和螺钉松动。

3注意有无泄漏介质。

七 停 机

主机停转。

1按下停止按钮。先关吸水管线阀门。

2停机后。后关排出管线阀门。

3临时停机(三个月以上)

临时停机后应马上进行的工作:

1把HAMMELMANN高压泵润滑油排放干净;

2切断电源;

暖气泄漏会腐蚀高压泵件)3关闭附近暖气(临时存放。

4防尘(用塑料膜把整机罩上)

哈莫尔曼高压泵 临时停机后再运转应注意事项

如电阻低于2MΩ,1测定电机的绝缘性能。应进行干燥处置;

2用煤油清洗机座池(清洗完后把煤油排放干净)

3其它按新开机(参阅4运转)处置;