品牌

生产厂家厂商性质

上海市所在地

气动三通球阀由GT型、DA型、AW型气动活塞式双作用或单作用(弹簧复位式)执行机构组成,有比例调节型(采用电-气阀门定位器,以电信号和压缩空气为动力,接受控制系统输入的0-10mA DC或4-20mA DC电流信号,改变球芯的旋转角度,可实现比例调节动作)。二位切换型(采用电磁换向阀、阀位回讯器,以AC220V或DC24V电源电压和压缩空气作动力,实现对流体介质的快速切换控制)

Pneumatic ball valve by the GT model, DA type, AW pneumatic piston double acting or single acting (spring return) actuator composed of a proportional control type (use of electricity - gas valve positioner to electrical signals and compression air-powered, the control system receiving input 0-10mA DC or 4-20mA DC current signal, change the angle of rotation of the ball core can achieve proportional control action). Two switch-type (electromagnetic valve, valve back to the hearing to AC220V or DC24V power supply voltage and compressed air, the fluid medium to achieve fast switching control)

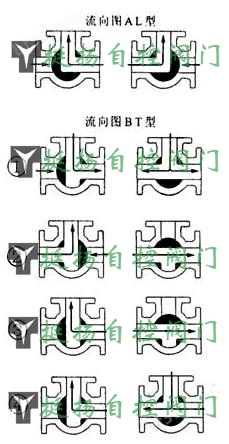

1.三通球阀有两座和四座密封结构,阀芯孔道有L型和T型两种结构形式,采用控制阀芯旋转角度,改变阀芯孔道与管道口的连接状态,可实现对三条支管不同的组合控制。三通球阀流通能力大,可控制气体、液体、蒸汽,更适用于控制高粘度,纤维颗粒状的流体。也适用于密封要求较严格的场合。

2.两阀座密封三通球阀具有结构紧凑、外形美观、密封性能好,它能实现对管道中介质流向的切换。也能使相互垂直的两个通道连通或关闭(如流向图A)

3.四阀座密封三通球阀具有造型美观、结构紧凑合理,它不仅可实现介质流向的切换,也可使三个通道相互连通,同时可关闭任意一个通道,使另外两个通道连通,灵活控制管路是介质的合流或分流(如流向图B)。

4.T型阀芯孔道可使三条正交的管道互相连通或切换,起分流或合流作用;L型孔道连接相互正交的两管道。使另一条孔道切断,起改变介质流向作用。

5.三通球阀的主要产品系列:如流向图所示选择工况;A图L型、B图T型(1-4)

1. There are two and four-way ball valve sealing structure, L-valve and T channels are two kinds of structure, the use of control spool rotation, change the channel and pipe spool port connection status, can achieve three different branch combination control. Ball valve flow capacity, can control the gas, liquid, vapor, but also for control of high viscosity, fiber granular fluid. Sealing requirements are more stringent for the occasion.

2. Two way ball valve seat sealing with compact structure, beautiful appearance, good sealing performance, it can achieve in the medium of the pipeline flow switch. Perpendicular to each other can also connect two channels on or off (such as the flow chart A)

3. Four-way ball valve with a valve seat sealing beautiful shape, compact structure, which not only enables media flow switch also allows three channels interconnected, and can close any channel, connected to the other two channels, flexible control pipeline is the media mixing or diverting service (such as the flow of Figure B).

4. T-valve allows three orthogonal channel pipes or switch connected to each other, from the confluence of diversion or the role; L-type channels to connect the two orthogonal channels. Another channel to cut off media flow from changes in the role.

5. Tee Ball's main product lines: the flow chart as shown in choice condition; A map L-type, B T-diagram (1-4)

主要零件材料及适用温度、介质Main parts and materials suitable temperature, medium:

| 公称通径mm DN(mm) | DN15-DN300 | |||

| 材料代号 Material Code | C(WCB) | P(304) | R(316) | |

| 主要零件 Main parts | 阀体 Body | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 球体 Sphere | 2Cr13、(304) | 1Cr18Ni9Ti | 1Cr18Ni12MoTi | |

| 阀杆 Stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12MoTi | |

| 阀座密封 Seat seal | 增强聚四氟乙烯 、对位聚苯 PTFE, polystyrene alignment | |||

| 填料 Filler | 聚四氟乙烯 、柔性石墨 PTFE, flexible graphite | |||

| 适用工况 Conditions apply | 适用介质 Medium | 蒸汽、水、油品 Steam, water, oil | 硝酸碱类腐蚀性介质 Nitrate alkali corrosive media | 醋酸类腐蚀性介质 Acetic acid corrosive media |

| 适用温度 Temperature | 聚四氟乙烯≤180℃,对位聚苯≤300℃ PTFE ≤ 180 ℃, the bit of polystyrene ≤ 300 ℃ | |||

应用规范Application Specification:

|

设计制造标准 Design and manufacturing standards

| 法兰尺寸标准 Standard flange size | 结构长度标准 Structure of the standard length | 检验试验标准 Inspection and Test Standard |

| GB/T12237-89 | JB/T79-94 HG20592 | GB12221-89 | GB/T13927-89 JB/T9092-99 |

| API6D | ANSI B16.5 | ANSI B16.10 | JB/T9092-99 |

| JPI7S-48 | JIS B2212~2214 | JIS B2002 | API598 |

性能规范Performance Specifications:

|

试验压力 Test pressure(Mpa)

| 公称压力(Mpa) Nominal pressure (Mpa) | 压力级(class) | JIS(Mpa) | |||||||

| 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 150 | 300 | 600 | 10K | 20K | |

| 强度试验 Strength test | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 | 3.1 | 7.8 | 15.3 | 2.4 | 3.8 |

| 密封试验 Seal test | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 | 2.2 | 5.6 | 11.2 | 1.5 | 2.8 |

主要技术参数和性能指标The main technical parameters and performance indicators:

| 公称通径 DN(mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| 流量系系数KV Flow system coefficient KV | 17 | 33 | 62 | 95 | 146 | 232 | 350 | 439 | 810 | 1205 | 1912 |

| |

| 公称压力 PN(MPa) | 1.6、2.5、4.0、6.4 | ||||||||||||

| 球芯转角 Corner ball core | 0~90° | ||||||||||||

| 球芯型式Ball type core | L型或T型 LorT | ||||||||||||

| 流量特性Flow characteristics | 快开式或比例调节式 The proportion of fast open or adjustable | ||||||||||||

| 连接形式 Connection form | 法兰式、管螺纹式(G") Flanged, threaded pipe (G ") | ||||||||||||

| 电动执行机构 Electric actuator | 型号 type | HL系列、3810R系列、PSQ系列、HQ或QB型 HL Series, 3810R Series, PSQ series, HQ or QB-type | |||||||||||

| 电源电压 Supply voltage | AC220V、AC380V、DC24V | ||||||||||||

| 作用形式 | 开关型/调节型(隔爆型) Switching / modulating (flameproof) | ||||||||||||

| 调节型 Regulated | 信号范围 Role of the form | 0~10mA、4~10mA 、1-5VDC | |||||||||||

| 开关型 Switching | 电信号 Electric signal | AC220V、AC380V、DC24V;反馈信号:有源触点信号或无源触信号 AC220V, AC380V, DC24V; feedback signal: active or passive touch signal contact signal | |||||||||||

| 气动执行机构 Pneumatic actuator | 型号 type | DA、GT系列;AW系列 DA, GT series; AW Series | |||||||||||

| 气源压力 Air pressure | 0.3~0.7MPa(净化压缩空气) 0.3 ~ 0.7MPa (clean air) | ||||||||||||

| 配用附件 Equipped with accessories | 电-气阀门定位器、空气过滤减压器、电磁阀、阀位回讯器、手动操作机构 Electric - gas valve positioners, air filter regulator, solenoid valves, valve back to the hearing, manual operating mechanism | ||||||||||||

| 调节型 Regulated | 输入信号 Input signal | 电信号:DC 0~10mA、4~10mA;气信号:0.14~0.55MPa Signal: DC 0 ~ 10mA, 4 ~ 10mA; air signal: 0.14 ~ 0.55MPa | |||||||||||

| 二位切换型 Two switch-type | 回信电压 Reply Voltage | AC220V/DC24V/DC110V | |||||||||||

管螺纹:L型

Pipe thread: L

| SIZE | d | L | H | D1 | B | W1 | W2 | h |

| 1/2" | 12.7 | 64 | 53 | 97 | 32.0 | 22.4 | 35.0 | 10-24UNC |

| 3/4" | 16.0 | 76 | 63 | 126 | 38.0 | 22.4 | 35.0 | 10-24UNC |

| 1" | 20.0 | 87 | 66 | 126 | 43.5 | 22.4 | 35.0 | 10-24UNC |

| 11/4" | 25.0 | 96 | 81 | 145 | 48.0 | 22.4 | 35.0 | 10-24UNC |

| 11/2" | 32.0 | 114 | 83 | 145 | 57.0 | 25.4 | 38.1 | 1/4-20UNC |

| 2" | 38.1 | 142 | 96 | 204 | 71.0 | 25.4 | 38.1 | 1/4-20UNC |

管螺纹:T型

Pipe Thread: T

| SIZE | d | L | H | D1 | B | F | G | W1 | W2 | h |

| 1/2" | 12.7 | 75 | 59 | 126 | 71.0 | 235 | 37.5 | 22.4 | 35.0 | 10-24UNC |

| 3/4" | 16 | 85 | 64 | 126 | 81.5 | 390 | 42.5 | 22.4 | 35.0 | 10-24UNC |

| 1" | 20 | 100 | 80 | 145 | 102.0 | 505 | 51.5 | 22.4 | 35.0 | 10-24UNC |

| 11/4" | 25 | 115 | 90 | 145 | 108.5 | 510 | 57.5 | 25.4 | 38.0 | 10-24UNC |

| 11/2" | 32 | 125 | 96 | 204 | 121.0 | 580 | 63.0 | 25.4 | 38.1 | 1/4-20UNC |

| 2" | 38.1 | 148 | 106 | 204 | 138.5 | 655 | 73.0 | 25.4 | 38.1 | 1/4-20UNC |

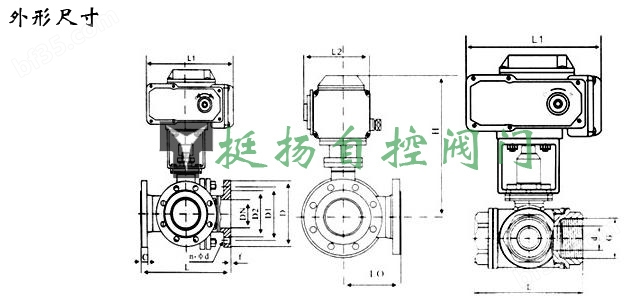

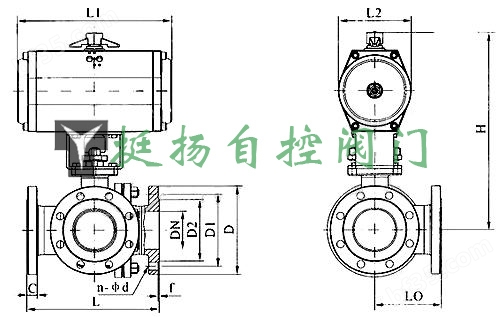

法兰式

Flange

| 主要尺寸 Main dimensions | 公称通径DN(mm) | |||||||||||

| 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| L | 150 | 150 | 180 | 200 | 220 | 240 | 260 | 280 | 320 | 380 | 440 | 500 |

| L1 | 75 | 75 | 90 | 1OO | 1 O | 120 | 130 | 140 | 160 | 190 | 220 | 275 |